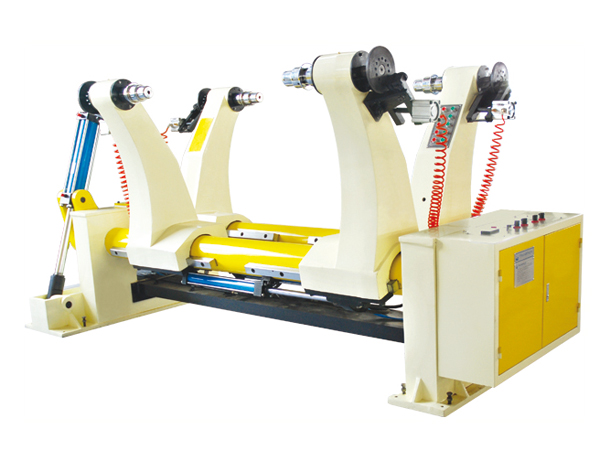

Our 2 ply corrugated board production line is also referred to as a single facer line. The single facer line is composed of a paper roll stand, a single facer unit and a paper cutting unit.

Production line parameters and requirements

1. Paperboard max width: 1600mm

2. Design speed: 80m/min

3. Work speed: 60m/min(5ply); 70m/min(3ply)

1. Paperboard max width: 1600mm

2. Design speed: 80m/min

3. Work speed: 60m/min(5ply); 70m/min(3ply)

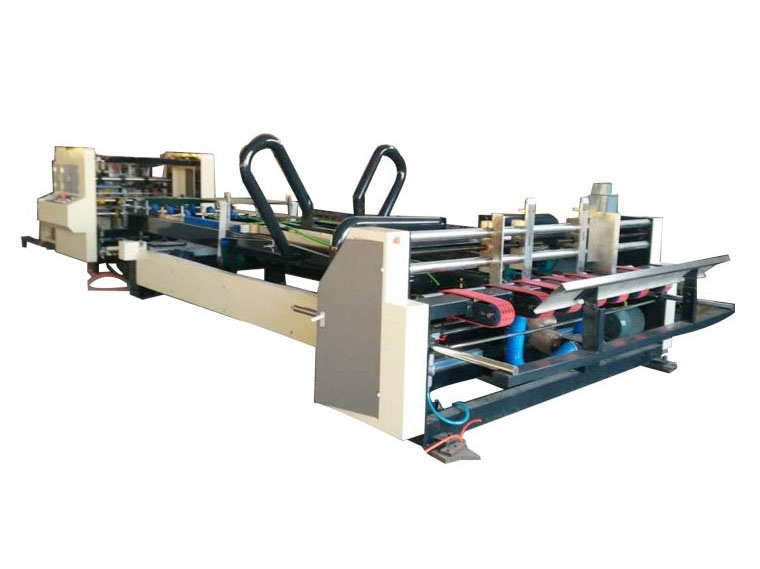

The corrugated box making machine is a highly efficient piece of equipment that uses corrugated board to assemble boxes. The machine performs printing, cutting, slotting and creasing processes to produce high quality cardboard boxes.

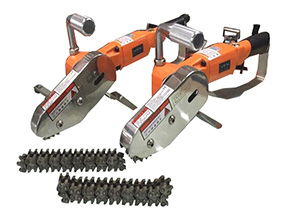

These rotary slotters are designed for efficient slotting functions during corrugated board production. They can perform continuous operation for high volume production operations. We produce both automatic and semi-automatic rotary slotter units.

This is our line of die cutters and waste strippers. The box die cutter is designed for manufacturing special corrugated boxes.

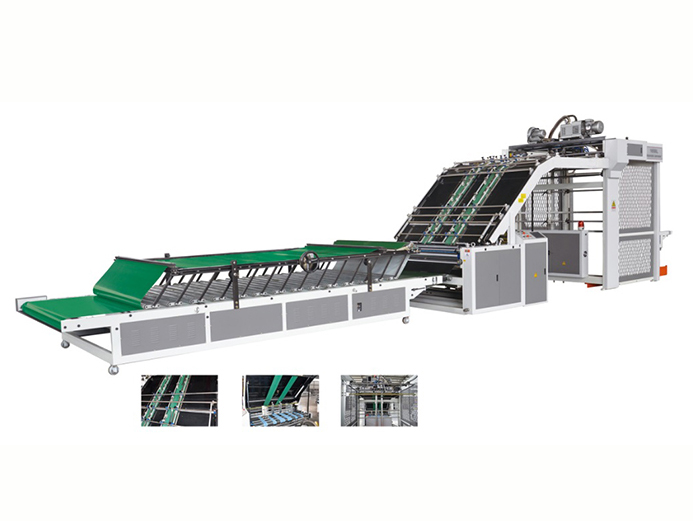

Our flute laminators are used to paste together corrugated boards in order to make cardboard that can then be further process for boxes or other paperboard products. The laminators can be used for 1, 2, 3 or 4 ply corrugated boards. We produce manual flute laminators, high table flute laminators, semi-automatic flute laminators and automatic flute laminators.

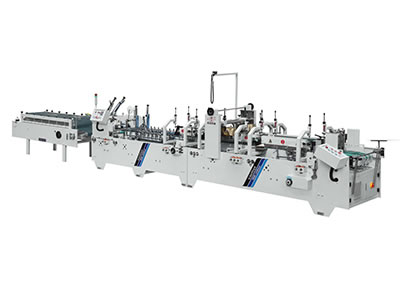

The cardboard box folder gluer machine is a multifunctional component that performs the final stage of box production. Our folder gluers apply a coat of glue to the flap of cartons and fold them into place for a solid hold.

For some types of paperboard boxes, the carton stitching machine is the last piece of equipment in the production line. The machine uses a sticking wire to hold together boxes at the flap to complete the box's structure. We produce a single head stitcher, twin head stitcher and arm wire stitcher

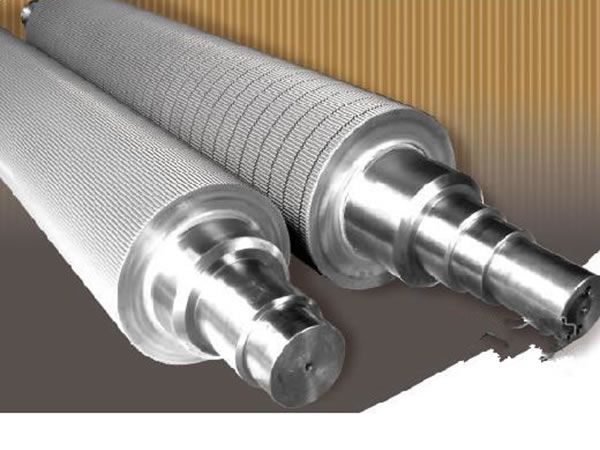

Slitter scorers are necessary components in the box production process as they crease and slit the corrugated board so that the cartons can be formed into the proper structure.

Our bundle tying machines were designed to minimize working time and labor for workers. The packaging equipment is easy to operate and can automatically package newspapers, magazines, paperboard, clothes, food and any number of other products.

The partition slotter and assemblers are designed to create boxes that have separate sections to keep the goods from becoming dislodged during transportation. The machines are used to create packaging that is often used for beverage shipping among other applications.

Our paper tube making machines take paperboard sheets and tightly roll them into tubes, while applying glue to keep the structure intact. Paper tubes are commonly used cardboard packages that can be used for a variety of shipping and storage purposes.

The hardboard production line is manufacturing equipment that has been specially designed to produce cardboard composite material between 2 to 6 plies thick. The hardboard is significantly stronger than standard cardboard and can be used to make signs and sturdy packages.

The glue trap board making machine is designed to produce a variety of pest control traps, including fly trap boards, mouse trap board and insect yellow boards.